热门关键词: ┆ 摩擦试验机 ┆ 鞋底弯折试验机 ┆ 耐磨试验机 ┆ ROSS耐折试验机

- 产品介绍

- 产品留言

主要配置: 传感器:美国传力 丝杆:台湾TBI 马达:伺服 外壳:坚美铝材 底座:电镀的烤漆底座

一、主要功能:

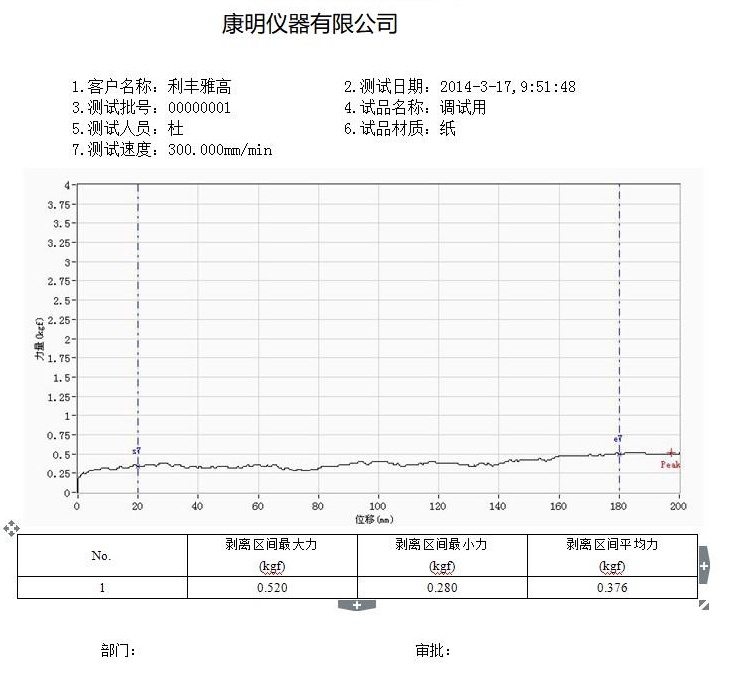

3.控制软件介绍 软件操作系统语言:简体中文/英文 力值单位:N,KN,Kgf,Lbf,长度单位:mm,cm,in可自由转换 自动归零:计算机接到试验开始指令,测量系统便自动归零; 显示方式:数据和曲线随试验过程动态显示; 结果再现:试验结果可任意存取,可对数据曲线再分析; 结果对比:多个试验特性曲线可用不同颜色迭加、再现、放大、呈现一组试样的分析比较; 紧急停机:设有急停开关,用于紧急状态切断整机电源;

|

4.控制方式: 计算机软件设定速度、设定负荷断裂(破裂)、运行时间等多种控制方式 自动判定材料断裂、压溃等并自动停机,可设定自动返回 曲线种类: 荷重-位移,荷重-时间,位移-时间。 应力-应变,应变-时间,应力-时间。 曲线纵横坐标可任意设置。 可提供的测试资料: 力量最大值,力量最小值,断裂值,上下屈服强度、抗拉强度、抗压强度、弹性模量、延伸率、剥离区间最大值、最小值、平均值等。具有过载,过流,过压,欠压,过速,行程等多重保护。 资料结果由目前国标通行之水晶报告格式导出。

二、技术参数: 容量选择:500KG (2,5,10,20,50,100,200,500,1000KG, 可选配) 传感器:美国传力高精度荷重元(可同时装多个感应器-选购) 精度等级:0.5级 有效测力范围:0.4%~100% 测力精度:示值的±0.5%以内 数据采样频率:200次/分 行程分辨率:1/1000000 试验机力值分辨率:最大负荷1/±300000码,内外不分档,且全程分辨率不变 负荷传感器基本配置:拉、压传感器(最大负荷) 有效试验宽度:400mm(可定做) 有效拉伸空间:800mm(不含夹具,可接受定做) 试验速度范围:0.01~500mm/min 速度控制精度:±0.2% (0.5级 ) 位移测量精度:示值的±0.5%以内 试台安全装置:电子限位保护 试台返回功能:手动或自动两种选择、试验结束后自动或手动返回试验初始位置 超载保护:超过最大负荷10%,机器自动保护 夹具配置:标准拉伸夹具一套(可根据产品特性进行定做) 主机尺寸:800×500×2100mm 电机:220V±10% 0.4KW,伺服电机 传动机构:高精度滚珠丝杆 主机重量:(约)180 Kg

|

Summary:

The servo universal materials tensile tester is applied to all kinds of hardware, metal, rubber and plastic materials,

shoes, leather, clothe,textiles, yarns, an insulator, wire and cable, for many kinds of materials. It tests every items

physical test performance. For example tear, strip, anti-pressure, bending, shearing force, peeling, tensile strength, laceration, adhesion force, three / four point bending, compression etc.

Theory:

This machine is a kind of electric tensile tester which uses the motor to drive ball screw to move fixture. Place the

sample between the upper and lower fixture, use a given speed to pull the upper fixture upward, and the upper load

cell with sensor to check tensile strength and convert the strength into voltage sign and output to the display screen.

And the strength value will be displayed automatically on the computer.

Standards:

ASTMD903, ASTM D412, GB/T16491,GB/T1040,GB/T8808,GB13022,GB/T 2790/2791/2792,

CNS- 11888,JIS K6854, PSTC-7, ISO 37, ISO 1798, BS EN 1979, BS EN ISO 1798 etc.

Features:

1. Adopting windows platform, and all the parameter settings can be processed in the dialog box, and it operates easily.

2. Using a single-screen operation; do not need to switch the screen

3. With three languages in Simplified Chinese, Traditional Chinese and English, the software interface can be switched

easily

4. The pattern of Test reports can be self designated; test data can be displayed directly in the main screen.

5. Choosing translational, comparative mode at the same time to make a number of curve data comparison

6. With a variety of measurement units, Measure In Imperial & Metric are switchable;

7. With self-return & auto-correction function

8. With automatic magnification function, in order to achieve the most appropriate size of the graphics

Specifications:

Items | Universal Tensile Test Machine |

Model | CM-8803 |

Max. Capacity | 5000, 10000Kg |

Unit | G, KG, N, LB can be exchanged |

Accurate Grade | 0.5grade |

Display Device | PC contoller to display |

Resolution | 1/200,000 |

Effective Accuracy | ±0.2%(0.5grade) |

Max. Effective Stroke | 800mm (column 143mm) |

Speed Range | 0-250mm/min (adjustable ) |

Motor | Servo Motor + High Precise Ball Screw |

Elongation Accuracy | 0.001mm |

Power | AC220V, 50/60HZ(custom-made) |

Standard Accessories | Tensile clamp, Tool kit, Computer system, English software CD, User manual |

Main Unit imagine

The drive system consist of servo control reduction motor, arc synchronous belt, ball screw,

moving steadily, high working efficiency, low noise, no pollution.

Electrical measurement and control system

1) With protect function of overload,over current, over voltage, displacement limit, emergency stop etc.

2) The controller can control more load sensor, high integration, stable and reliable, easy to adjust

3) When finished testing, automatic stop

4) Control system with programmable amplifier A/D conversion, digital I/O, counting and pulse happen (PWM),

and other functions in one

5) Mechanical zero setting, automatic force measurement, zero setting, calibration and save, highly integrated

control circuit

Software and software interface

1) Based on Windows operation platform, the software adopting modulus design, with simple operation and

powerful functions

2) The control panel has defined all the control parameters, data dealing method and report content also the

form, different test can be set according to the control panel.

3) Program adopting open database structure, integrated the GB, ISO,ASTM,JIN, DIN testing methods

and can customized according to special requirements

4) With internet interface, can transmit, save and print data. Can connect enterprise Internal LAN and Internet.

5)Can edit and set the report form freely, also can print out the testing data.

| 共 1 条记录,共 1 页,当前是第 1 页 |

公司以“质量至上、服务第一、为客户创造最大价值!”的经营理念和求实创新、精益求精的企业精神

关注我们 / FOCUS ON US

东莞市康明检测仪器有限公司 @ 2018版权所有